a.k.a. kluge (keep the hacker tradition alive! [see 4th paragraph])I think the simpler way would be to ...

BTW with just an off the cuff janky solution ...

Topton Jasper Lake Quad i225V Mini PC Report

- Thread starter ReturnedSword

- Start date

Notice: Page may contain affiliate links for which we may earn a small commission through services like Amazon Affiliates or Skimlinks.

Given the recent thermal discussions, I vote they install solidstate active cooling chips after all Vibrating back passive pressure sounds like it should keep one from noisy blowers.

Any way you could measure or even guess at the thickness of that copper shim? I used a .005" thick shim on mine. My shim was placed under the large copper heatsink with paste between case / shim / heatsink / CPU which brought idle temps down 10°C from 40°C to 30° for Win11 when testing. With pfSense bare metal, I get 40°C idle temps. But that is using two different monitoring methods. Also, was there thermal paste on both sides of the copper shim - or not?Not anymore, the factory applied the copper plate in between, sees my previous post.

BobS

Last edited:

You need to put thermal paste at every interface. By if you put the shim between the case and copper block, did you also drill holes for the screws? I'd imagine it would be easier to put the shim between the CPU and the copper block, although it could be beneficial to have the shim under more pressure between the copper block and case with the screws.Any way you could measure or even guess at the thickness of that copper shim? I used a .005" thick shim on mine. My shim was placed under the large copper heatsink with paste between case / shim / heatsink / CPU which brought idle temps down 10°C from 40°C to 30° for Win11 when testing. With pfSense bare metal, I get 40°C idle temps. But that is using two different monitoring methods. Also, was there thermal paste on both sides of the copper shim - or not?

BobS

I do have paste on each surface.You need to put thermal paste at every interface. By if you put the shim between the case and copper block, did you also drill holes for the screws? I'd imagine it would be easier to put the shim between the CPU and the copper block, although it could be beneficial to have the shim under more pressure between the copper block and case with the screws.

Yes I made cutouts on the shim for the two screws. You can't really drill .005" copper cleanly (at least I couldn't) so an exacto knife to make the cutouts for the two screws.

When I did mine, I wanted to sand off the paint that was under the heatsink so it was just as easy to place the shim there. Pasted both sides and then used a clamp to press the heatsink and shim to the case. While loosely clamped, I inserted the two screws into the heatsink and aligned them to their threaded holes in the case. Then I clamped that stack tight. I then tightened the screws. Had a nice even squeeze-out of paste around the case to heatsink interface. I used a thin coat of Artic Silver ceramic paste on all surfaces applied using a single-edge razor blade to keep it nice and even. Ceramic paste is a bit thicker than other pastes and can be tricky to spread evenly - hence the need for the single-edge blade.

You can certainly add the shim on the bottom but if your motherboard is the same, there are two nylon strips parrallel to the CPU/GPU and are at the same height as the CPU/GPU faces. I'm assuming those are there to help insure pressure is equalized across the chip surfaces so they don't get cracked.

Be interested in the temps you get if when you finish putting it together to compare a bottom mounted shim vs a top mounted one.

BobS

Last edited:

I'm not sure we can directly compare temps since I have one of the cheaper ones with the smaller heatsink. But as I said above, just by applying some pressure behind the CPU location with something like I was doing with my finger in the video a couple pages back, I've reduced the temps so much that it doesn't even throttle after an hour and a half of Prime 95 (small FFT). In fact it's not even close, it stays at around 65°C. I'm still double checking everything but it seems it's holding up.I do have paste on each surface.

Yes I made cutouts on the shim for the two screws. You can't really drill .005" copper cleanly (at least I couldn't) so an exacto knife to make the cutouts for the two screws.

When I did mine, I wanted to sand off the paint that was under the heatsink so it was just as easy to place the shim there. Pasted both sides and then used a clamp to press the heatsink and shim to the case. While loosely clamped, I inserted the two screws into the heatsink and aligned them to their threaded holes in the case. Then I clamped that stack tight. I then tightened the screws. Had a nice even squeeze-out of paste around the case to heatsink interface. I used a thin coat of Artic Silver ceramic paste on all surfaces applied using a single-edge razor blade to keep it nice and even. Ceramic paste is a bit thicker than other pastes and can be tricky to spread evenly - hence the need for the single-edge blade.

You can certainly add the shim on the bottom but if your motherboard is the same, there are two nylon strips parrallel to the CPU/GPU and are at the same height as the CPU/GPU faces. I'm assuming those are there to help insure pressure is equalized across the chip surfaces so they don't get cracked.

Be interested in the temps you get if when you finish putting it together to compare a bottom mounted shim vs a top mounted one.

BobS

I'm pretty sure the CPU was making contact with the copper block, but probably just barely. Putting the mobo without paste over the heatsink assembly didn't have any give between them.

I also have some copper plates of different thicknesses, I'll have to cut them up to test, but I might do that just for fun.

Forgot to ask was your unit from cwwk?just by applying some pressure behind the CPU location with something like I was doing with my finger in the video a couple pages back, I've reduced the temps so much that it doesn't even throttle after an hour and a half of Prime 95 (small FFT). In fact it's not even close, it stays at around 65°C. I'm still double checking everything but it seems it's holding up.

Yeah it's the exact listing in the link above.Forgot to ask was your unit from cwwk?

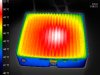

That's a nice toy! It looks like a lot of heat is transferred to... is that the display port?Got to play a bit with a new toy, would be interesting to see the distribution of heat on one of those new cases with heatpipes. This is with Prime95 running for more than an hour, temps appear to be stabilized at 70°C.

View attachment 26863

Crickey got the 6 port v5 on its way, will see if I can give it a similar testing.Yeah it's the exact listing in the link above.

Haha, whoa... good catch! Looks like front 2-port USB assembly? From pics, it has a metal casing so good heat conducting, I guess?That's a nice toy! It looks like a lot of heat is transferred to... is that the display port?

That's the top USB port. The bottom one has a USB dongle attached. I don't think it's hot though, I think it is reflecting IR from the heat sink above.That's a nice toy! It looks like a lot of heat is transferred to... is that the display port?

What I found curious is the words painted white seem cooler. I recently saw a video from a science channel on YouTube about why some people in the desert wear black cloaks instead of white, and the answer wasn't that clear-cut, but at least part of the reason was probably that even though black absorbs more heat, is also radiates heat at a higher rate. Now I want to test a regular heatsink versus a black painted heatsink.

Last edited:

Yes both sides thermal paste. I'm unable to measure the thickness, I do not have the tools measuring so thin. its quit stiff but not thick.Any way you could measure or even guess at the thickness of that copper shim? I used a .005" thick shim on mine. My shim was placed under the large copper heatsink with paste between case / shim / heatsink / CPU which brought idle temps down 10°C from 40°C to 30° for Win11 when testing. With pfSense bare metal, I get 40°C idle temps. But that is using two different monitoring methods. Also, was there thermal paste on both sides of the copper shim - or not?

BobS

This is interesting. I assume the device is running horizontally. Looks like the heatsink saturates after some times and runs at 46-50°C. The case, while still being "blue", is at a whopping 42-44°C which is still rather hot.Got to play a bit with a new toy, would be interesting to see the distribution of heat on one of those new cases with heatpipes. This is with Prime95 running for more than an hour, temps appear to be stabilized at 70°C.

Could you redo the test keeping the mini PC vertical? I'm curious to see how much the chimney effect will affect cooling once air start rising inside the heatsink and take away heat.

I don't see a lot of talk about Qotom units here, atleast not lately. I've heard good things about them and their website, support and BIOS downloads seem to be way better than CWWK for example. This unit is a bit cheaper than the newest N5015 ones from CWWK, albeit it has i225 based NICs. But if I understood correctly the B3 should be good? Apparently Yanling is the manufacturer of these boxes.

Maybe off-topic for this thread but I've also been wondering about buying a Yanling box that Protectli also offers and flash their coreboot into it. I would miss out the N5105 performance but those slower ones should still be good for gigabit, no?

Maybe off-topic for this thread but I've also been wondering about buying a Yanling box that Protectli also offers and flash their coreboot into it. I would miss out the N5105 performance but those slower ones should still be good for gigabit, no?

Think there was discussion about them very early on in the thread (I read the entire 120 pages) Its a bit too familiar though with build quality, heatsink contact, warranty, general support issues with all of them it seems regardless of brand or manufacturer.I don't see a lot of talk about Qotom units here, atleast not lately. I've heard good things about them and their website, support and BIOS downloads seem to be way better than CWWK for example. This unit is a bit cheaper than the newest N5015 ones from CWWK, albeit it has i225 based NICs. But if I understood correctly the B3 should be good? Apparently Yanling is the manufacturer of these boxes.

Maybe off-topic for this thread but I've also been wondering about buying a Yanling box that Protectli also offers and flash their coreboot into it. I would miss out the N5105 performance but those slower ones should still be good for gigabit, no?

Cwwk has so far appeared to be better in these regards (hardware and support) but as you can see just a few pages back one unit was not making proper contact with the cpu resulting in a noticeable temperature drop. Some of these issues are fixable if you are good with computers and can do some DiY though.

Sure you may get units cheaper from others, prices change daily. I think its better to stick with i226 series, its the newer chipset and slightly less wattage used but generally you should be fine with i225 also.

Some other deals here:

here

here

here

here (people like this one a lot since its the latest revised model from cwwk v5, but this was cheaper 2 weeks ago around £145) prices change often.

Forgive me if this has been discussed before, but it always seemed to me that most of these are sourced from the same factories, just rebranded by each different store. I wouldn't expect much difference hardware-wise, just maybe BIOS, but then again I'm not sure if these small operations are writing their own firmware like Netgate does. Maybe some of them are better at sourcing BIOS updates from the manufacturer, but are they actually different in hardware between stores?

I had a much better experience with "CWWK PC Store" than with "Kingnovy Computer Store" which I don't even think had the units in stock, and gave me a fake shipping number to something shipped to another city, and then tried to re-ship after the latest supposed delivery date via free shipping when I'd paid for DHL. I also ordered and had to cancel from some Topton store.

I had a much better experience with "CWWK PC Store" than with "Kingnovy Computer Store" which I don't even think had the units in stock, and gave me a fake shipping number to something shipped to another city, and then tried to re-ship after the latest supposed delivery date via free shipping when I'd paid for DHL. I also ordered and had to cancel from some Topton store.

Although a powerful and cool little machine - maybe as a server, but can't use virtualization (ie: Proxmox) or bare metal PFSense/OPNSense - also, it only has one network interface onboard (can use USB device) - but not worth it as a firewall (IMHO)Have anyone considered using Mac Mini (M1 or M2) as a small home lab/firewall ? Thoughts?